Continuing our work with microfluidics modeling, simulating and validating gradient generation devices is our latest undertaking at Flow Science. Diffusion based gradients are an integral part of many complex biological processes. One example is how wounds heal due to chemotaxis, where the cells migrate along a chemical gradient. Over the past few years, various approaches to establish and study diffusive gradients have surfaced, but they all suffer their share of problems.

Atencia, et al., have proposed an innovative microfluidic gradient generator – the microfluidic palette – that attempts to overcome the known problems with previous approaches.

Previous Approaches and Associated Problems

There are three principal approaches to establishing diffusive gradients: laminar flows, membranes and hydrogels, and free diffusion. Each has its merits, but, as mentioned, they also have accompanying troubles.

The standard approach for studying and establishing gradients in microfluidic devices involves the use of laminar flows. This approach is very simple, but shear stresses are generated due to convective flows. Shear stress may alter the cellular response. For example, biased cellular migration and asymmetrical mass transport may occur.

A more-recent development is to avoid the convective flows by establishing diffusive gradients include using rigid membranes and hydrogels. However, membranes and gels reduce the diffusion speed affecting the transient development of a gradient.

Finally, an approach has been developed that brings two fluid plugs in contact to allow free diffusion between them. The approach is however limited to 1-D flows only. Also, once the gradient is established, convective flows have to be used to modify the diffusive gradients, which brings one back to the earlier problem of shear stress generation in laminar flows.

In this blog, I will discuss the principle behind the new approach to diffusive gradient generation proposed by Atencia, et al., and present some results of FLOW-3D simulations of such effects.

The Microfluidic Palette

The principle behind the microfluidic palette is decoupling the convective flow from diffusion without using membranes or gels, leading to the following advantages:

- Delivery of material (cells or soluble material) without shear stress

- Generation of overlapping gradients with different spatial locations

- Dynamic control over the gradients

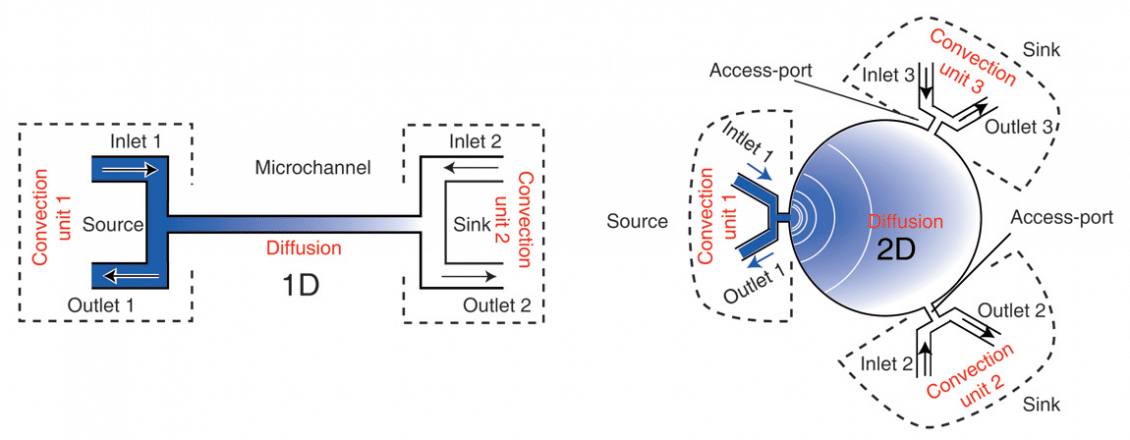

The designs of the microfluidic palettes proposed by Atencia, et al., are shown above. In the 1-D case, a mass balance in Convection unit 1 shows that matching the flow rates at Inlet 1 and Outlet 1 prevents flow through the main microchannel while allowing transfer through diffusion. The Convection unit 1 acts as a perfect source. The 2-D case is simply an extension of the 1-D case, with more than two convection units.

FLOW-3D Simulations

In the 1-D microfluidic palette animation below, a clean decoupling of the convective cells from the main central microchannel can be seen be through the plotted streamlines. The streamlines are all restrained to the convection units only and not even a single one leaks out into the microchannel, indicating excellent decoupling of convection and diffusion. The evolution of source concentration can be seen in the plot, which becomes visibly constant by the end of the animation.

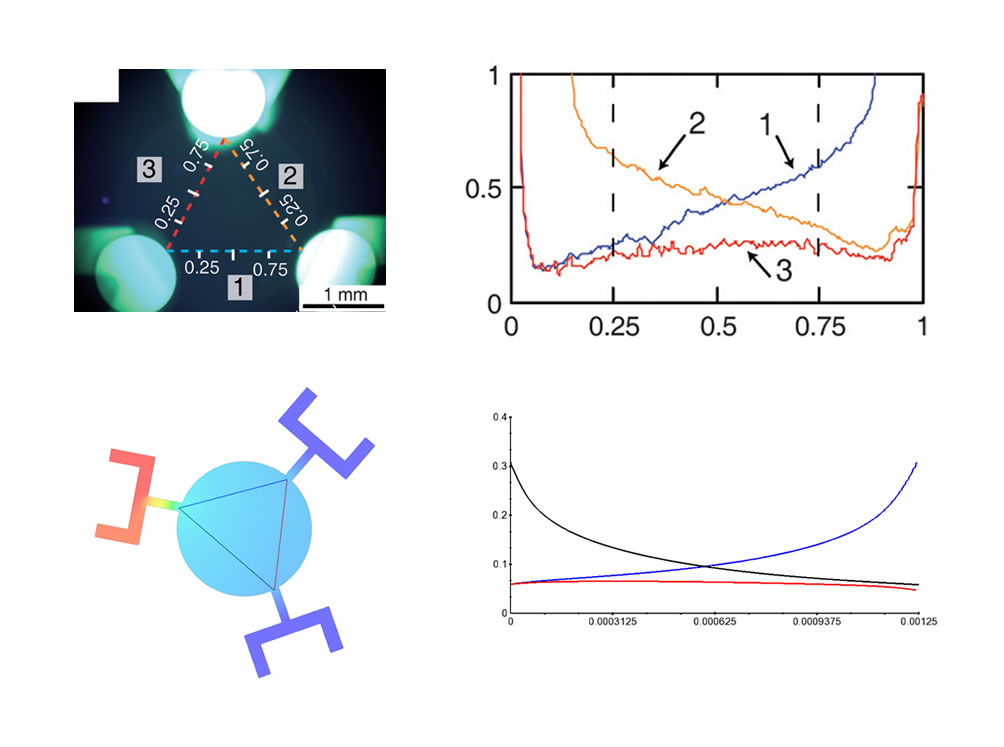

The 2-D microfluidic palette demonstrates a spatio-temporal control on the generated gradients. The source and sink are rotated at an angular velocity. Also, after every t seconds, the active access port is deactivated and the next port is turned on. To see the live status of the diffusion inside the chamber, three line probes are placed in the simulation (marked in red, blue and black, respectively, in the bottom right window of the simulation below).

Comparison with the Experimental Results

FLOW-3D results are in good agreement with the experimental results in terms of the evolution of concentrations inside of the chamber. The images below show a snapshot in time for both the experimental results and the simulation results. Notice that the experimental results are normalized. Also, experiments use fluorescence intensity to indicate the concentration of the source. In the simulation, FlowSight’s line probes are used to study the concentration between the 3 access ports.

FLOW-3D’s good validation against the experimental results paves a way of simulating other types of gradient generators in the future. There are more gradient generators like non-linear gradients generators, which I will discuss in future blogs.

References

Atencia J, Morrow J, Locascio L.E., The microfluidic palette: A diffusive gradient generator with spatio-temporal control, The Royal Society of Chemistry 2009